DIY Outdoor Sectional Building Guide: 3 Easy Steps

Today we are going to build an outdoor sectional! I will also show you how to easily adjust the measurements to change the size of the sectional to fit your needs!

All My Favorite Tools Can Be Found Here

*This post contains affiliate links. I will receive a commission for items purchased through these links at no extra cost to you. I appreciate your support. Please read all labels and follow all manufacturer safety recommendations when working with any tools or equipment recommended.

All Materials in this post can be found here!

Watch a video tutorial Here!

Let’s begin!

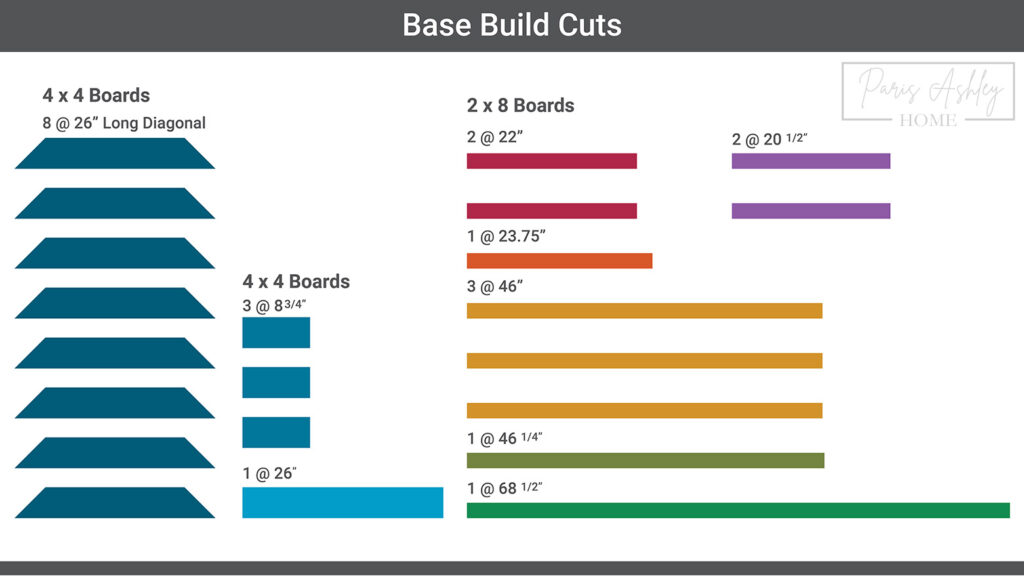

Below I have included a cut list and placement, please refer to these when I’m going over the how-to process! I based all my cuts off the 24” x 24” Hampton Bay cushions listed above from The Home Depot.

After building my sectional, I drafted basic renderings and perfected my cuts and plans. You can either cut all the pieces in the beginning or go phase by phase. The choice is yours!

Step 1: Cutting and Assembling the Base

- Grab your 4 x 4 boards and cut 8 – 26” pieces on a diagonal(trapezoid), 26” is the max width of the diagonal cut. Next, cut 3 – 8 3/4” and 1 – 26” straight cuts. The will be your supports for the corners and the long side of the sectional.

- Next, let’s assemble the outer sides of the sectional, grab your 3” and 4” star head screws, wood glue and impact driver. Lay out 4 of your 26” diagonal cuts in a square on a flat surface. Start with one corner and add wood glue to the end of the board. If you have big enough corner clamps, you can use them here, I did not, so I just used my body weight to hold the piece in place while I added 2 3” screws and one 4” screw to each side of the corners. Repeat until all corners are attached and both squares are made.

- At this point with my two end squares and 4 support pieces I laid out my cushions for spacing, gathered my measurements (which I laid out for you in the cut list above) and started cutting my 2” x 8”s for the rest of the base.

- This is your opportunity to adjust the measurements if you want a 4 x 3 sectional, instead of a 5 x 2 (this refers to the seats/cushions across). Or whatever size you want to make this. Simply add or subtract 24” from the side you want to lengthen or shorten. You will have to recalculate where your 4 x 4 support pieces will sit, I centered them on my long side.

- Once all your 2” x 8”s are cut, grab your Pocket-Hole Jig, and place 4 pocket holes on each end of your boards, there is usually a nicer side of the wood, I choose the side that has more imperfections to face the inside of the build (less seen) and place the pocket holes.

- At this point we are ready to sand, stain & seal the base. Before we sand, use wood filler and fill any cracks in the wood or any screws that are visible. Once the wood filler is dry, use your orbital sander and sanding discs, sand all sides and ends of your boards first with 80 grit, then 120, and lastly with 220.

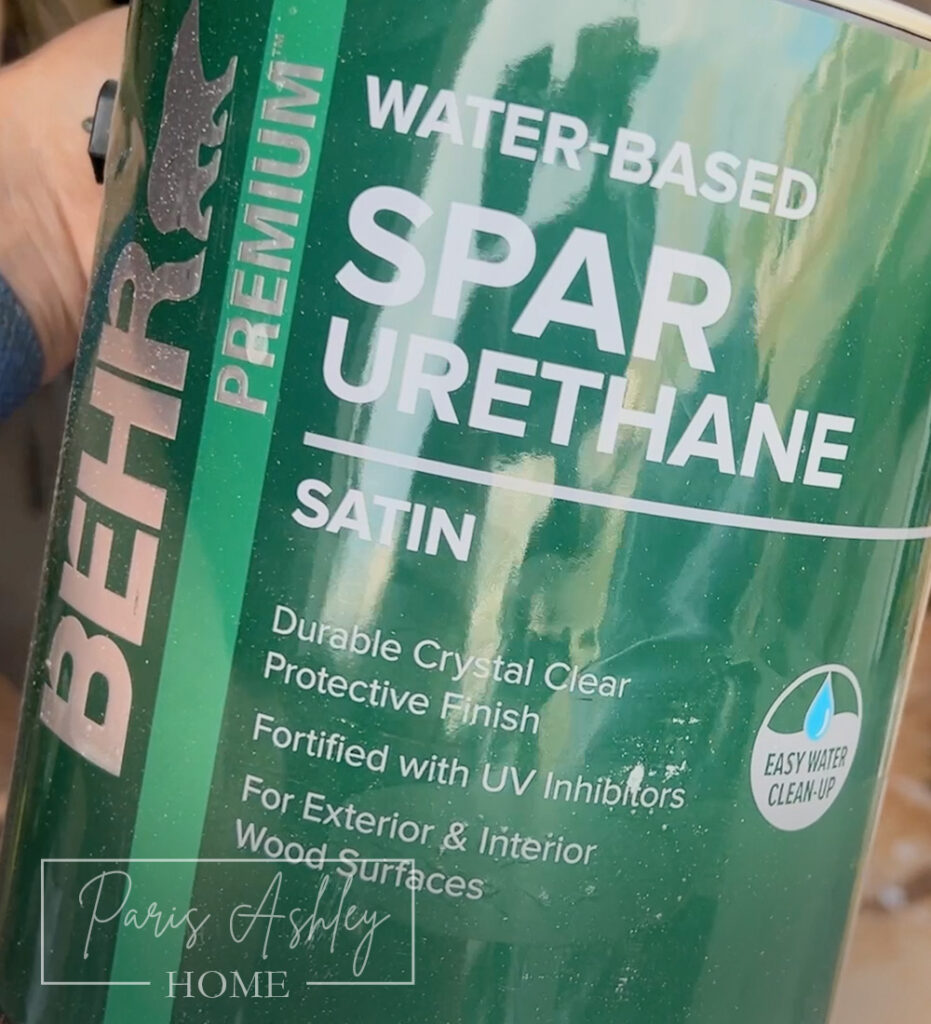

- After you finish sanding it’s time to stain, we will start with a wood conditioner, this gives the stain the best chance for an even application without splotches. Give the wood conditioner 30 mins to soak in before staining. The actual stain color is up to you. I used one coat of White Antique for a white wash to reduce the yellow from the wood, then two coats of my favorite stain, Early American. I used oil based stains, which requires 24 hours to dry before applying a water based stain. After 24 hours, we can seal our boards. I apply 3 coats of the Spar Urethane, sanding with a 220 grit sanding block between each coat of sealer.

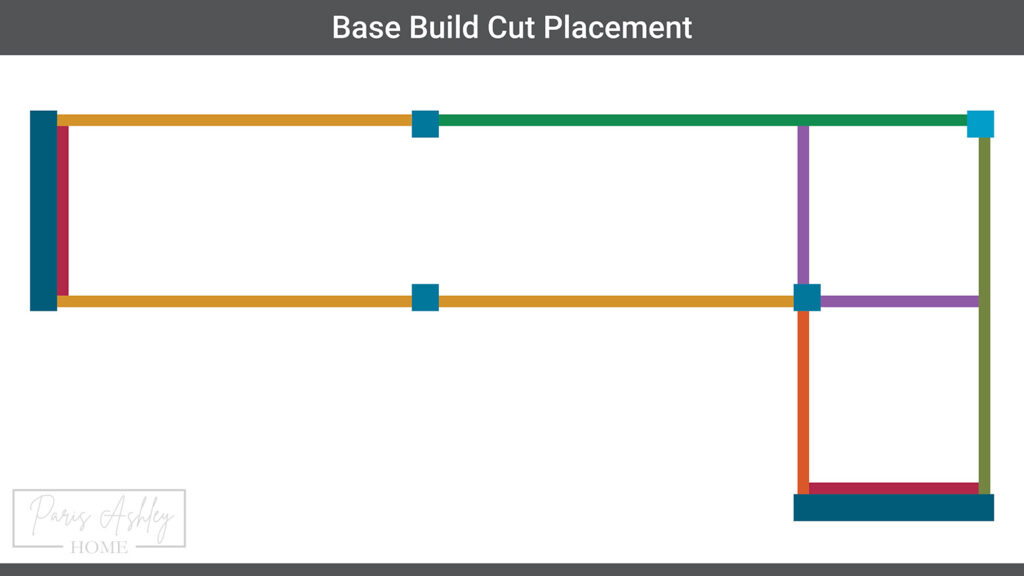

- We are ready to assemble the base! Reference the renderings for proper placement of the boards and support pieces. Using spare 2” x 4” blocks, place them under the 2” x 8”s for the proper base height (view image). Attach the 2” x 8”s to the 4” x 4”s using 3” star head screws and 2.5” kreg pocket screws.

Before we move to the next phase, grab your caulk gun and 100% clear silicone caulk and caulk anywhere two pieces of wood meet each other to prevent any water from getting in and extending the life of this sectional as long as possible!

Step 2: Congrats the base is built! Let’s move on to the slat support, slats and back!

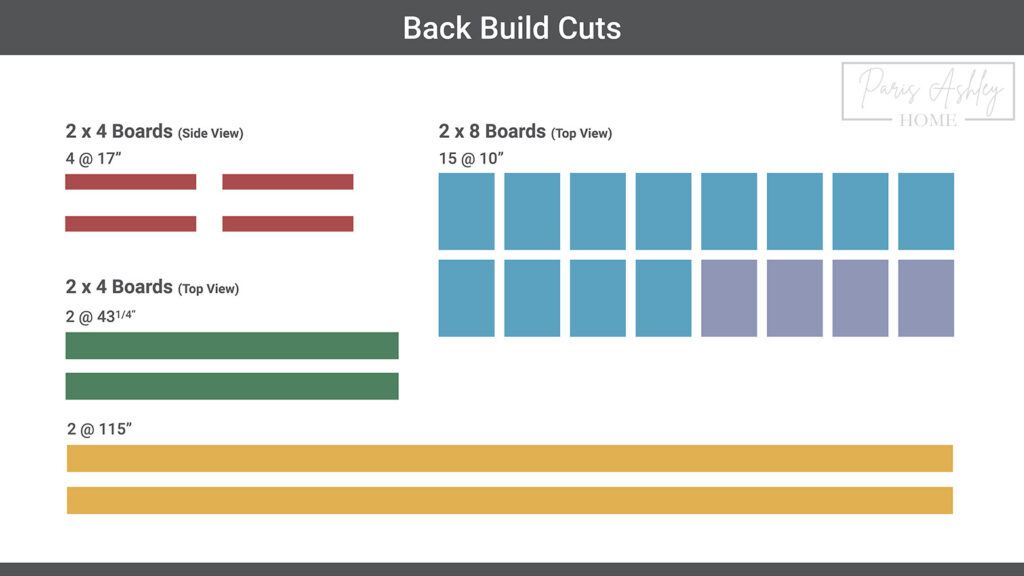

- Before we start on the slat supports and slats, reference the 3rd set of renderings, and cut your 2” x 4”s and 4” x 8”s for the backs. Add pocket holes to the 15 @ 10” – 4” x 8” boards, 2 on each end on the same side. Grab your 4 long 2 x 4”s and add 2 pocket holes on each end of the shorter boards, and 3 pocket holes on each end of the longer boards. No pocket holes needed on the 17” – 2” x 4”s. Sand all your boards with 80, 120 & 220 grit.

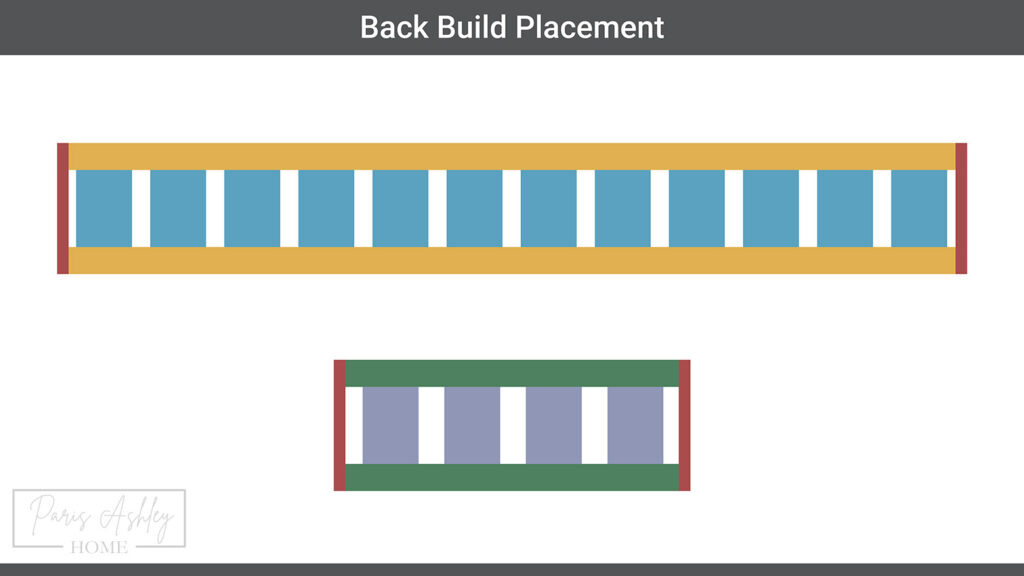

- Assemble the backs upside down, use spare wood to raise the long 2 x 4” to the height of the 17” – 2 x 4”s. Use 2.5” pocket hole screws and wood glue to assemble. Once both back frames are assembled, dry fit the frames on the base of the bench.

- When everything fits perfectly, evenly space out the 10” boards. 4 on the smaller back side, 11 on the larger back side, roughly 3” apart. Use wood glue pocket screws and clamps to assemble the back, make sure the pocket holes are facing the backside, for a better aesthetic.

- Now that the backs are built, go ahead and wood condition, stain and seal your built backs, your 2” x 2”s and 1” x 4”s the same way you did the base. I added silicone caulk to all the pocket holes to prevent any water damage in the future, you could use pocket hole plugs instead here, but silicone caulk is much more cost and time effective, and you’ll never be looking at the back if it’s against a wall. If your bench is sitting in the open, I would suggest pocket hole plugs, sanding and staining them to match.

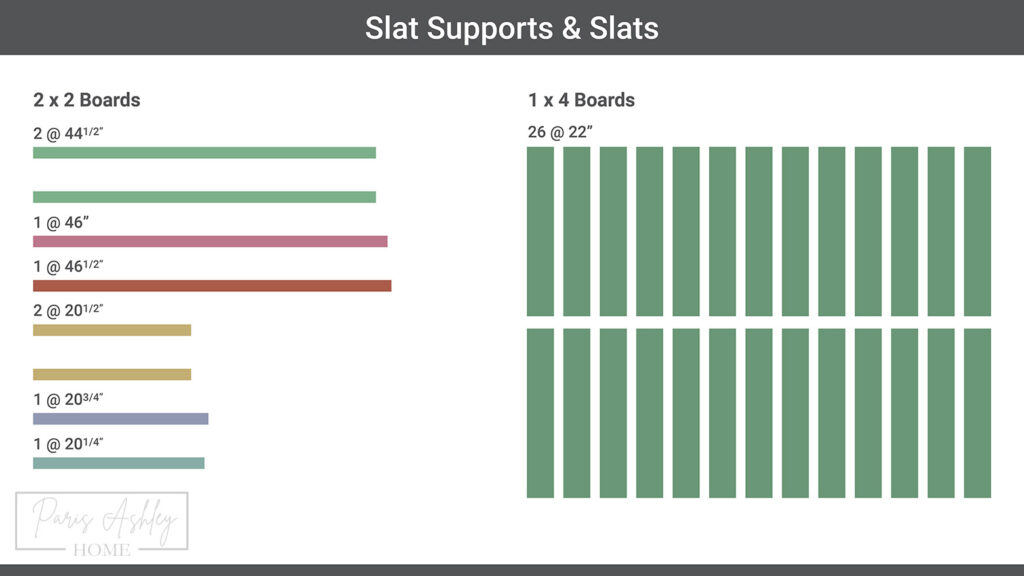

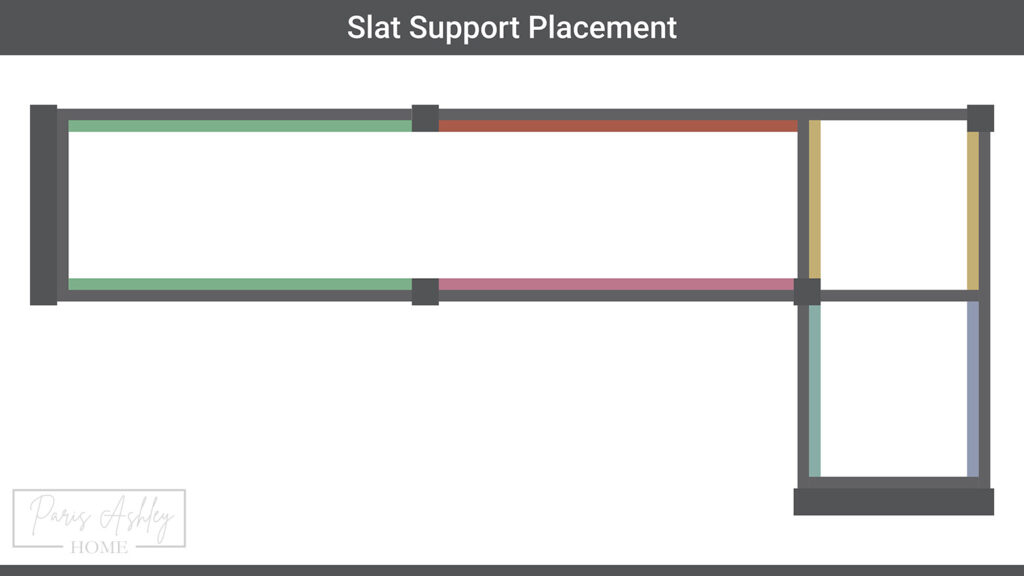

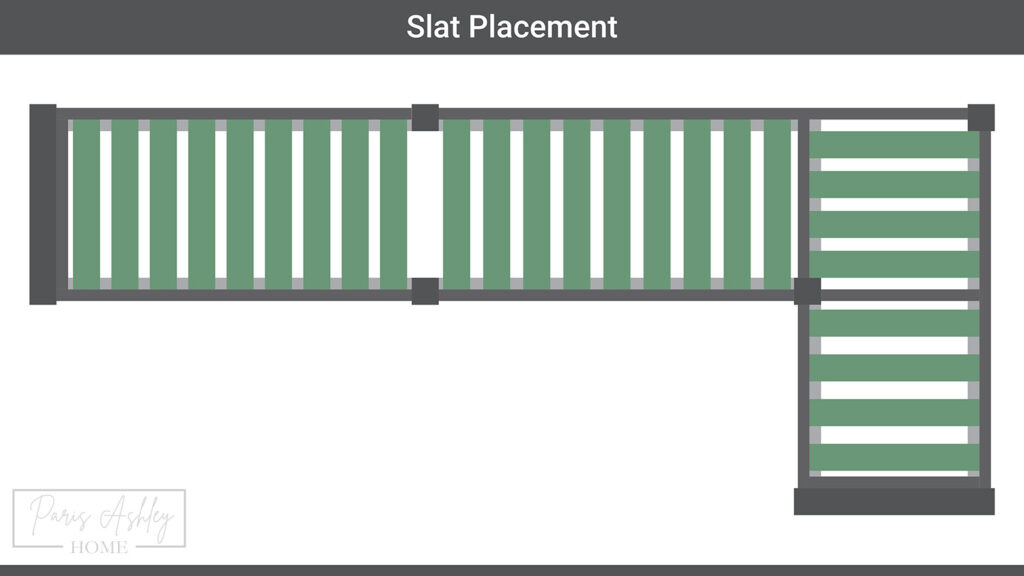

- Once your boards are sealed and dry, reference the 2nd set of renderings I provided and cut all your slat support pieces and slats. Dry fit your pieces first and make any cut adjustments necessary, they should fit perfectly, but we are human and it’s best to double check!

- Grab your 2” star head screws, countersink bit & impact driver. Pre-drill 6 countersink holes and screws into the longer pieces of slat supports and 4 into the shorter pieces. Use a slat to ensure the placement of the slat support is the perfect height for the slat to sit level with the base of the bench. Using a clamp to hold the slat support, grab your impact driver and screw all the slat supports in.

- Once all the slat supports are installed, grab your silicone caulk and caulk all the seams as well as the screw holes.

- Grab your slats, 18ga brad nailer, 1.5” brad nails. Evenly space them out across your bench and use 3 nails on each end of your slats. Again, grab your silicone caulk and caulk all the slat seams and nail holes. Note: using the silicone caulk is NOT necessary, but I believe it will extend the life of this outdoor sectional.

Step 3: Congrats, your base is finished! Let’s install the backs!

- Grab two cushions, two clamps, tape measure, rubber mallet, drill, countersink bit, impact driver, 3” star head screws and your two assembled and sealed back pieces.

- Place two cushions on one side of the bench, I started on the short side. Grab your assembled back and put it in place, if necessary, use your rubber mallet to tap it in place, sitting just above the cushions and angled back slightly. This ended up being 12” from the bottom of the back to the top of the 4” x 4”. Grab your drill and countersink bits and drill 4 holes on each side, using your impact driver and 3” screws, screw in the back to the 4” x 4”s on each side.

- Repeat the process on the long side, I did have an extra set of hands here and clamps did help as the long side was much heavier than the short side.

- Lastly, caulk the screw holes. Wait 24 hours for the silicone to dry before putting your cushions on.

CONGRATS, YOU BUILT A SECTIONAL!!!

Enhance your outdoor space with cushions, pillows, and decorative items from The Home Depot to create a cozy retreat.

Want even more inspiration and behind-the-scenes action? Follow me on Instagram @parisashleyhome! I share all my DIY projects, home decor tips, and the latest updates on my journey to creating a beautiful, cozy home. Join me and let’s inspire each other to tackle more DIY adventures.

Watch a video tutorial Here!

Follow ParisAshleyHome on social for more DIY Tutorials!

Follow on Instagram, Subscribe on YouTube, Pin on Pinterest, Follow on Facebook, Follow on TikTok, Shop on LTK!